Mechanisms

What is AMALPHA?

AMALPHA resin-to-metal bonding makes the use of the “anchor effect.”

Once resin is forced into a microscopically roughened surface made up of flask-like pores and solidifies, it becomes impossible to extract it, so it would remain there even after fracture. This implies that force required to cause a fracture of an AMALPHA-bonded component would be higher than the breaking strength of the resin.

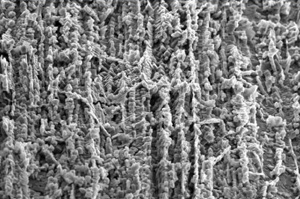

Monitoring anchor profile by creating a resin replica

By dissolving the metal part of a metal and resin-bonded molding, it is possible to make a resin replica of a roughened surface. The mushroom-like profile present on the resin replica, as revealed by SEM, proves that the metal and resin were bonded by the “anchor effect.”

Al surface

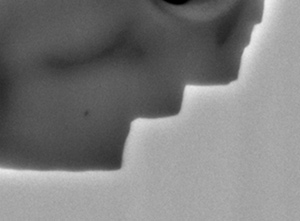

Replicated surface of resin

Sealing performance of tight metal and resin adhesion

The sealing performance achieved by AMALPHA is exhibited due to the close adhesion between metal and resin. The photos below show x100,000 SEM images of a cross section of AMALPHA resin-to-metal bonding. These reveal direct adhesion between metal and resin with no air present at the interface. Water or air cannot pass through the interface since there is no clearance between metal and resin.

*Dark granules inside the resin are carbon black particle compounded in the resin.

metal-to-resin bonding cross section

by AMALPHA

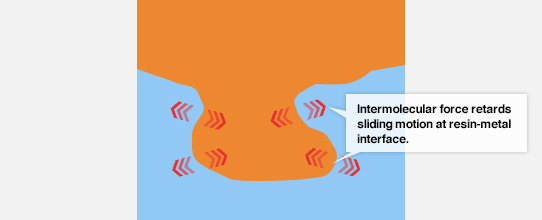

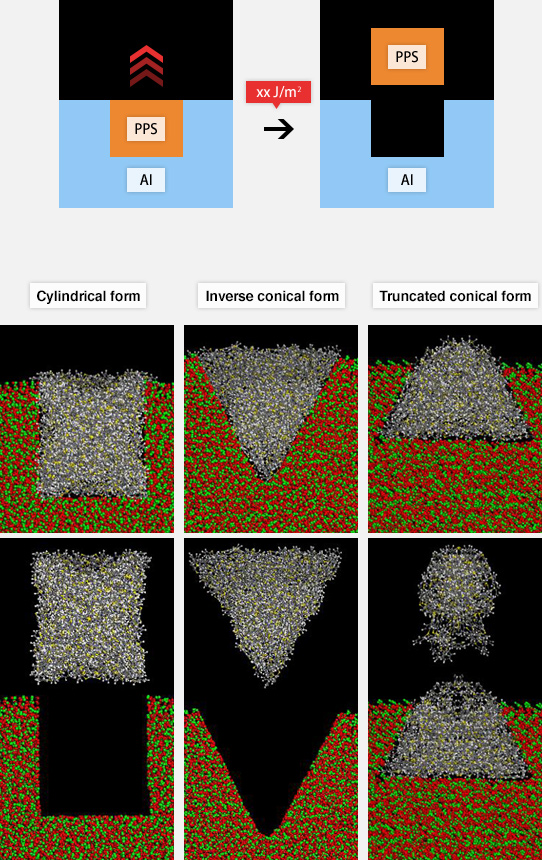

Increased intermolecular force within micropores

A supercomputer analysis of the intermolecular force acting at the resin-metal interface formed into various rough surface profiles showed an increased intermolecular force inside flask-like micropores. This rise in intermolecular force is expected to retard the resin’s sliding motion within micropores during thermal cycles.

| Intermolecular force | 0.122J/m2 | 0.115J/m2 | 0.196J/m2 |

|---|---|---|---|

| Anchor effect | 0 | 0 | >2.074J/m2 |

| TOTAL | 0.122J/m2 | 0.115J/m2 | >2.270J/m2 |