Durability

Performance/Control

AMALPHA bonding is a direct bonding between metal and resin with no adhesives or other low-durability materials at the interface. Consequently, the bonding will not degrade until the degradation of resin or metal.

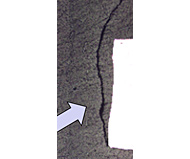

Rendered image of non-bonding-interface failure of resin

Thermal cycle and high-temperature, high-humidity tests conducted by MEC involving accelerated degradation of test specimens showed no degradation originating from the AMALPHA interface.

Results of durability test

| Ordinary state | After thermal cycle test | After high-temperature, high-humidity test | |||||||

|---|---|---|---|---|---|---|---|---|---|

| -40℃,30min⇔150℃30min 1,000 cycles |

85℃,85%RH After 1,000 h |

||||||||

| Al | SUS | Cu | Al | SUS | Cu | Al | SUS | Cu | |

| PPS | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Phenol | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Epoxy | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

- ○:1.0 x 10-10 Pa∙m3/s max. in helium leak test (lower than leak detection limit)

Cracks in resin

after thermal cycles

An example of crack development after thermal cycle testing of unreinforced resin with no glass fiber (aluminum-phenol bonding test specimen)