Selective etching table

The following table shows the metal combinations for which selective etching can be performed.

-

S

Applicable(no etching for protected objects)

-

S

Applicable (no etching for protected objects)

-

A

Applicable(etching rate ratio is 10 times or more)

-

B

Applicable (others)

-

Not applicable

| Metal for etching (to be removed) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | Zn | Fe | Co | Ni | Sn | In | Bi | Cu | Pd | W | Mo | cITO | NiCr (Cr20%) |

SUS304 | |||

| Metal for protection (to be left or protected) | Al | A | A | S | A | A | S | A | S | S | S | ||||||

| Zn | A | ||||||||||||||||

| Fe | S | A | S | B | S | S | S | S | S | ||||||||

| Co | A | A | A | A | A.S | S | S | S | |||||||||

| Ni | S | A | S | A | A | A | S | S | S | S | |||||||

| Sn | A | S | S | S | S | S | |||||||||||

| In | A | A | A | B | A | S | |||||||||||

| Bi | A | A | S | B | S | S | S | S | |||||||||

| Cu | A | A | A | A | A | B | |||||||||||

| Pd | S | S | S | S | S | S | S | S | S | S | S | A | A | ||||

| W | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |||

| Mo | S | A | A | A | A | A | A | A.S | A | A | A | ||||||

| Ag | S | S | S | S | S | S | S | S | S | S | S | ||||||

| Pt | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| Au | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| Si | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| Ti | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| Ta | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| Nb | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| clTO | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |||

| NiCr (Cr20%) |

S | S | S | S | S | S | S | S | S | S | S | S | |||||

| SUS304 | S | S | S | S | S | S | S | S | S | S | S | S | |||||

- Selective etching may be not avalible depending on the components of substrate. SUS304 and SUS316 and SUS430 have a similar trend.

- Without asking for details, it may be difficult to determine whether selectively etching is avalible or not. Please contact us first.

Selective etching

This is an etching technology that dissolves a specific metal when two or more different metals coexist, without affecting (or melting) the other metals.

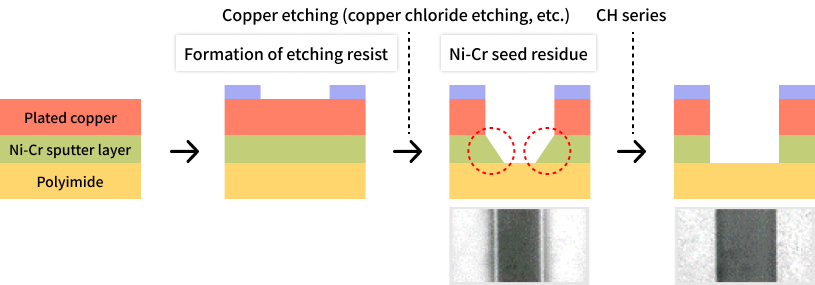

Nickel-chromium alloy remover

MEC REMOVER CH series

From the copper and nickel-chromium co-existing substrate, nickel-chromium alloy can be selectively etched without damaging the copper surface. The CH series is useful for removing nickel-chromium film residue or etching the embedded resistance film on a 2-layer, sputter-type flexible substrate.

Etching example

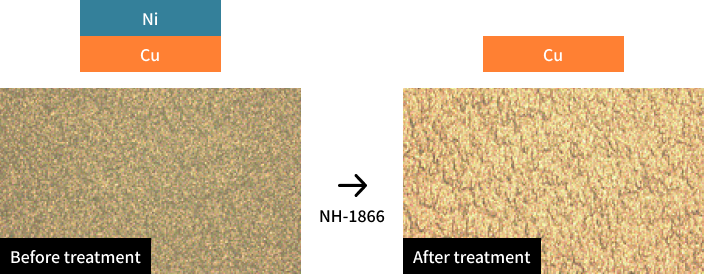

Nickel remover

MEC REMOVER NH-1860 series

This series performs selective etching of nickel on the copper and nickel co-existing substrate without damaging the copper surface. It is useful in forming copper posts using nickel as a barrier layer or in forming patterns through reverse transfer process using nickel as a base metal.

Etching example

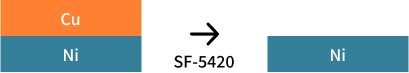

Copper remover

MECBRITE SF series

This slightly alkaline etching agent is able to etch copper without damaging co-existing nickel or solder.

Etching example

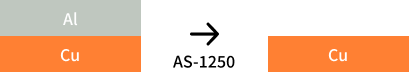

Aluminum remover

MEC aluminum smoothing agent AS-1250

This is an alkaline type etching solution to form a smooth aluminum surface by removing burr or scratches on aluminum surfaces. It does not damage copper surface.

Etching example

Dissimilar metal roughening,selective roughening

Other metal roughening

MEC NICKEL ROUGHENER

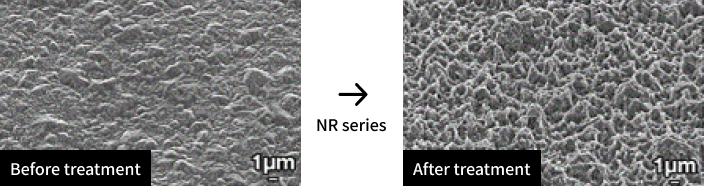

NR series(Under development)

This etching solution produces a unique surface topography having a superior anchor effect by etching a nickel surface. It is useful as a pretreatment agent for dry film lamination on the nickel surface.

Etching example

Selective roughening

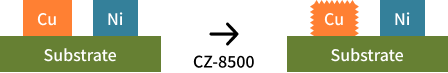

MECetchBOND CZ-8500

This slightly alkaline etching agent enables etching of copper film without damaging co-existing nickel or solder.

Etching example

We will suggest the product best suited to your needs.