MECetchBOND UT series

- UT series creates a unique roughening of rolled copper.

Due to its uniquely, uniform roughened copper topography an extraordinary copper-to-resin adhesion is achieved. - UT series is widely applicable where a high level of adhesion is required, such as pre-treatment for build-up resin lamination, dry film lamination or solder mask application.

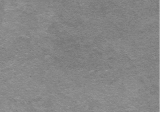

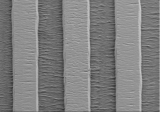

Surface observation

| Untreated | |

|---|---|

| Electrolytic copper foil |

Rolled copper foil |

|

|

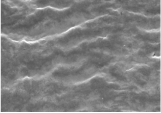

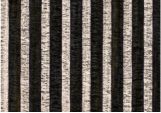

| H2SO4-H2O2 type:0.5μm | |

|---|---|

| Electrolytic copper foil |

Rolled copper foil |

|

|

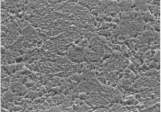

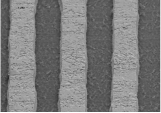

| UT-4100:0.5μm | |

|---|---|

| Electrolytic copper foil |

Rolled copper foil |

|

|

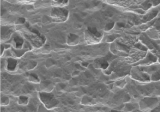

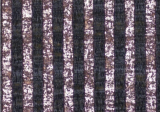

| UT-4120:0.8μm | |

|---|---|

| Electrolytic copper foil |

Rolled copper foil |

|

|

Performance

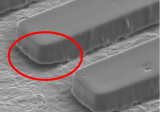

DFR adhesion

UT-4100 improves the adhesion with DFR.

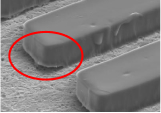

| Untreated | |

|---|---|

| Tip | Corner |

|

|

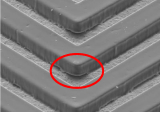

| H2SO4-H2O2 type:0.5μm | |

|---|---|

| Tip | Corner |

|

|

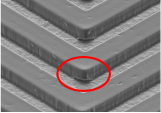

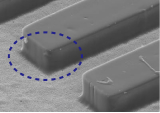

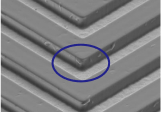

| UT-4100:0.5μm | |

|---|---|

| Tip | Corner |

|

|

- Copper foil: Hyper anneal copper foil (HA foil)

Process flow: UT-4100 treatment → DFR patterning (L/S=40/40μm)

Wiring linearity / Appearance uniformity

UT series improves the pattern linearity and appearance uniformity

| Untreated | |

|---|---|

| SEM | Metal microscope |

|

|

| H2SO4-H2O2 type:0.5μm | |

|---|---|

| SEM | Metal microscope |

|

|

| UT-4100 0.5µm | |

|---|---|

| SEM | Metal microscope |

|

|

- Copper foil: Hyper anneal copper foil

Process flow: UT-4100 treatment → DFR patterning → Etching → DFR stripping

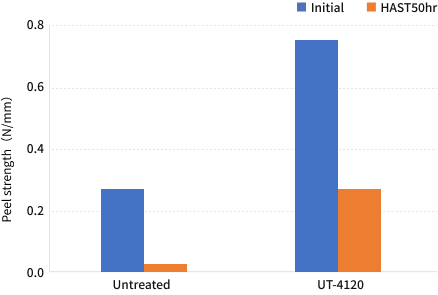

Solder mask adhesion

UT-4120 improves the adhesion performane against solder mask.

Contact us first.

Inquiry about products

We will suggest the product best suited to your needs.