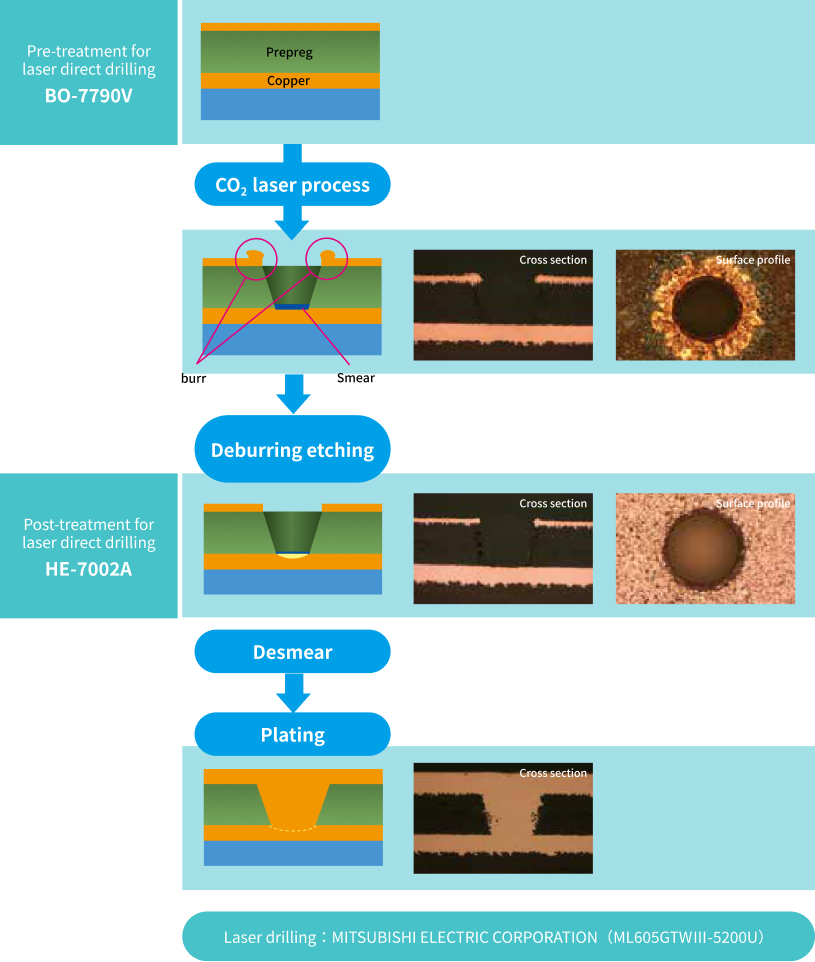

Pre-treatment for laser direct drilling

MEC V-Bond BO-7790V

BO-7790V is a H2SO4-H2O2 type microetching agent.

It creates a surface topography that increases the energy absorption rate of the direct laser used.

Post-treatment for laser direct drilling

MEC PowerETCH HE-7002A

A microetching agent that efficiently removes copper splatters and burrs generated during direct laser processing using a CO2 laser.

Contact us first.

Inquiry about products

We will suggest the product best suited to your needs.