- Chemicals for pattern formation with semi-additive process<SAP>

- Chemicals for pattern formation with modified semi-additive process<M-SAP>

- Chemicals for palladium catalyst residue removal

Chemicals for pattern formation with semi-additive process<SAP>

Here is the etching agent for copper seed layer and Ti seed layer stripping especially for SAP process.

These are available to minimize undercut and line width reduction, and available to form fine patterns.

MECBRITE QE series

This series is a H2SO4-H2O2 type quick etching agent for Cu seed layer etching.

Features of MECBRITE QE series

- Minimizes reduction in line width.

- Can obtain desired patterns with minimal undercut.

- Minimize the roughening of copper surface and maintain a smooth copper surface.

- Its etching rate can be adjusted according to the desired productivity because it is an additive type.

- High chlorine resistance and stable etching speed.

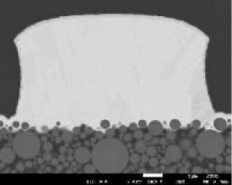

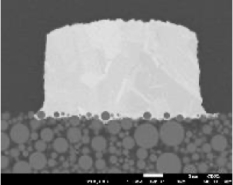

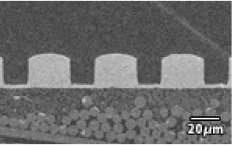

Examples of pattern formation

| Untreated |  |

|---|---|

| Conventional 1.0μm |  |

| QE series 1.0μm |  |

- L/S=10/10μm, Seed layer: electroless copper 0.5μm,

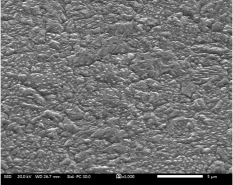

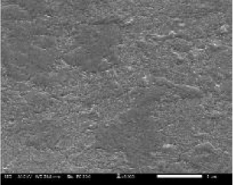

Surface topography

| Untreated |  |

|---|---|

| Conventional 1.0μm |  |

| QE series 1.0μm |  |

- Our electrolytic plated plate

MEC REMOVER QT-1100

A sulfuric acid-based quick etching agent for removing Ti seed layers.

Features of MEC REMOVER QT-1100

- Minimizes the pattren width reduction and undercut with little impact on copper.

- Has excellent liquid stability as it does not contain hydrofluoric acid, ammonia, or hydrogen peroxide.

- Can remove 50 nm Ti seed within 60 seconds by flood-immersion treatment.

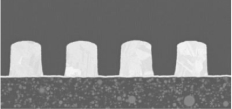

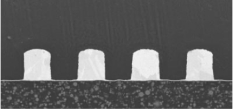

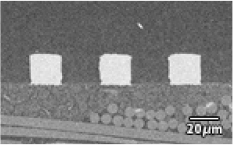

Examples of pattern formation

| Untreated |  |

|---|---|

| After Cu seed etching (QE series) |

|

| After Ti seed etching (QT-1100) |

|

- Seed layer: Sputtered copper 150nm / Ti 50nm, L/S=3/3μm

Chemicals for pattern formation with modified semi-additive process<M-SAP>

Here is the etching agent for copper seed layer for M-SAP process.

These are available to minimize undercut and line width reduction, and available to form fine patterns.

MECBRITE CI-7200

This series is a H2SO4-H2O2 type etching agent for Cu seed layer etching.

Features of MECBRITE CI-7200

- Can obtain desired patterns with minimal undercut.

- Minimizes reduction in line width because of its excellent etching performance on copper foil.

- Available as a copper seed remover for SAP and M-SAP.

- Its etching rate can be adjusted according to the desired productivity because it is an additive type.

Treatment steps

- CI-7220 30°C (standard), spraying Treatment time: 40-60 sec. (standard)

- Rinse

-

Post treatment

3-5% NaOH, at room temperature, spraying

Treatment time: 20 sec. (standard) - Rinse

- Dry

- In the case of CI-7220

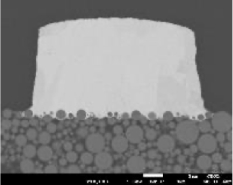

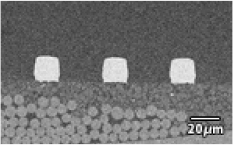

Examples of pattern formation

| Untreated |  |

|---|---|

| Conventional |  |

| CI series |  |

- 50 μm pitch

Seed layer: Cu foil 3 μm + electroless Cu 1 μm

Chemicals for palladium catalyst residue removal

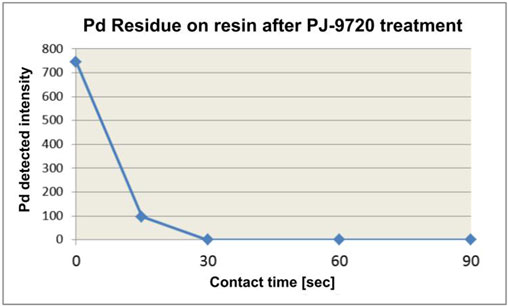

MEC REMOVER PJ-9720

It is a hydrochloric acid-based Pd catalyst residue remover. It is an especial ideal for removing Pd catalyst residue remaining on insulating resin in the SAP process.

Features of MEC REMOVER PJ-9720

- Can selectively remove Pd catalyst without damaging the conductor pattern.

- Greatly improves insulation reliability.

- Inhibits abnormal deposition of electroless Ni plating.

- Can be used for both dipping and spraying applications.

- Can be used at relatively low temperature (25℃ to 40℃)

- Automatic control and feeding is available.

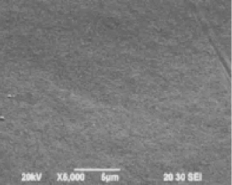

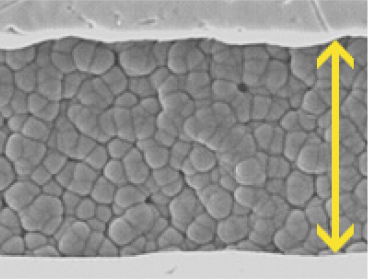

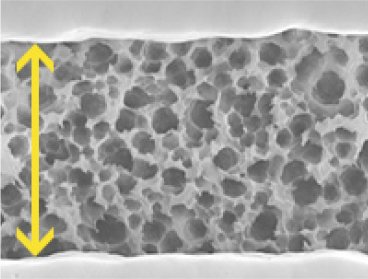

Deposition of electroless nickel on the resin

| Untreated | PJ-9720 |

|---|---|

|

|

- Pattern space 10µm

Relationship between dwell time and detected Pd intensity (35°C spraying)

We will suggest the product best suited to your needs.